Valve yolowera

M'kope lino tidzakambirana za ma valve olowetsa ndi kutuluka, komabe, tisanalowe mwatsatanetsatane, tidzayika zinthu izi kuti timvetsetse bwino. Injini imafunikira njira yogawira mpweya wotulutsa ndi kutulutsa, kuwongolera ndikuwasuntha kudzera munjira zambiri kupita kumagulu ambiri, chipinda choyaka moto komanso kutulutsa kosiyanasiyana. Izi zimatheka kudzera mu njira zingapo zomwe zimapanga dongosolo lotchedwa kugawa.

Injini yoyatsira mkati imafunikira kusakaniza kwamafuta-mpweya, komwe, kukawotchedwa, kumayendetsa njira za injiniyo. Muzinthu zambiri, mpweya umasefedwa ndikutumizidwa kuzinthu zambiri zomwe zimapangidwira, kumene mafuta osakaniza amayesedwa kudzera mu machitidwe monga carburetor kapena jekeseni.

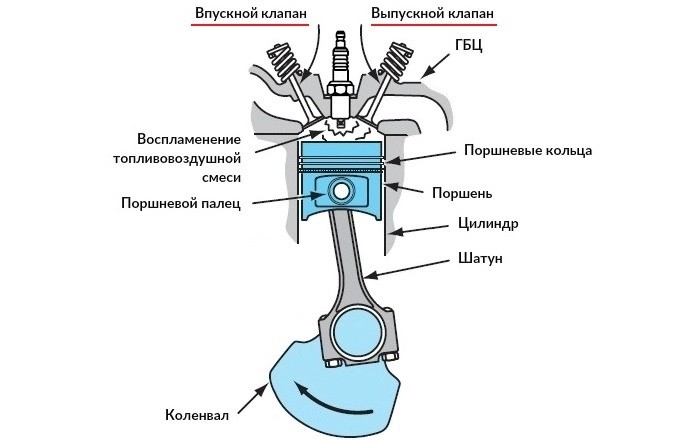

Kusakaniza komalizidwa kumalowa m'chipinda choyaka moto, kumene mpweya uwu umayaka ndipo, motero, umasintha mphamvu yotentha kukhala mphamvu yamakina. Ntchito ikamalizidwa, ndikofunikira kuti zinthu zoyaka moto zichoke m'chipindamo ndikulola kuti kuzungulira kubwereze. Kuti izi zitheke, injiniyo iyenera kulamulira kulowetsedwa ndi kutuluka kwa gasi mu silinda iliyonse, izi zimatheka ndi mavavu olowetsa ndi kutuluka, omwe adzakhala ndi udindo wotsegula ndi kutseka njira panthawi yoyenera.

ZINTHU ZINTHU ZOYANG'ANIRA

Kugwiritsa ntchito injini ya sitiroko zinayi kumakhala ndi magawo anayi:

POLOWERA

Panthawiyi, valavu yolowetsa imatsegulidwa kuti mpweya utuluke kunja, zomwe zimapangitsa kuti pisitoni igwe, komanso kuyenda kwa ndodo yolumikizira ndi crankshaft.

KUPANIZA

Panthawi imeneyi, ma valve olowetsa ndi kutuluka amatsekedwa. Pamene crankshaft imazungulira, ndodo yolumikizira ndi pisitoni imawuka, izi zimapangitsa kuti mpweya wolowetsedwa mu gawo lolowera uwonjezere kuthamanga kwake kangapo, kumapeto kwa kupsinjika kwa sitiroko mafuta ndi mpweya wothamanga kwambiri.

MPHAMVU

Pa sitiroko yamphamvu, pisitoni imayamba kutsika pomwe mpweya / mafuta osakanikirana amayatsidwa ndi spark plug, ndikupangitsa kuphulika mkati mwa chipinda choyaka.

MASULIDWA

Pomaliza, panthawiyi, crankshaft imatembenukira kumanja, motero imasuntha ndodo yolumikizira kuti pisitoni ibwerere mmwamba pomwe valavu yotulutsa mpweya ili yotseguka, ndikupangitsa kuti mpweya woyaka utulukemo.

KODI ma valves olowera ndi otulutsa ndi chiyani?

Ma valve olowera ndi otuluka ndi zinthu zomwe ntchito yake ndikuwongolera kutuluka kwamadzi kapena gasi; omwe amagwiritsidwa ntchito polowetsa ndi kutulutsa injini ya sitiroko zinayi nthawi zambiri amakhala mavavu okhala.

Kodi mavavu amenewa ndi otani? Mavavu ndi mbali zolondola za injini ndipo amachita ntchito zinayi zofunika kwambiri pakugwira ntchito kwa injini:

- Kutsekereza magawo otaya.

- Kuwongolera kusinthana kwa gasi.

- Masilinda otsekedwa ndi Hermetically.

- Kutaya kwa kutentha komwe kumachokera ku kuyaka kwa mpweya wotulutsa mpweya, kuusamutsira kumalo oyikapo mipando ya valve ndi malangizo a valve. Pa kutentha mpaka 800ºC, valavu iliyonse imatsegula ndi kutseka nthawi 70 pa sekondi imodzi ndipo imapirira kusintha kwa katundu wokwana 300 miliyoni pa moyo wa injini.

NTCHITO

MAVAVU A INLET

Valavu yolowetsa imagwira ntchito yolumikiza zochulukitsa zolowera ku silinda malinga ndi nthawi yogawa. Monga lamulo, amapangidwa ndi chitsulo chimodzi chokha, chitsulo chokhala ndi chromium ndi zonyansa za silicon, zomwe zimapereka kukana bwino kutentha ndi ntchito. Madera ena achitsulo, monga mpando, tsinde, ndi mutu, nthawi zambiri amawumitsidwa kuti achepetse kuvala. Kuzizira kwa valve iyi kumachitika chifukwa chokhudzana ndi kusakaniza kwa mpweya wa mafuta, komwe kumataya kutentha kwake kwakukulu, monga lamulo, pokhudzana ndi tsinde, ndipo kutentha kwake kumafika 200-300 ° C.

MAVAVU OTSITSA

Valavu yotulutsa mpweya imagwirizana nthawi zonse ndi mpweya wotulutsa mpweya pa kutentha kwambiri, choncho iyenera kukhala yolimba kwambiri kuposa ma valve olowetsamo.

Kutentha komwe kumasokonekera mu valavu kumatulutsidwa kudzera pampando wake ndi 75%, sizosadabwitsa kuti kumafika kutentha kwa 800 ºC. Chifukwa cha ntchito yake yapadera, valavu iyi iyenera kupangidwa ndi zipangizo zosiyanasiyana, mutu wake ndi tsinde nthawi zambiri zimapangidwa ndi chromium ndi magnesium alloy steel, chifukwa zimakhala ndi kukana kwambiri kwa okosijeni komanso kutentha kwambiri. Pamwamba pa tsinde nthawi zambiri amapangidwa kuchokera ku silicon chrome. Kwa matenthedwe matenthedwe, pansi ndi ndodo zodzaza ndi sodium zimapangidwa, popeza izi zimakhala ndi ntchito yotumiza kutentha kumalo ozizira, kuchepetsa kutentha kwa pansi mpaka 100ºС.

MTUNDU WA MAVAVU

Chithunzi cha MONOMETALLIC VALVE

Amapangidwa mwanzeru ndi kutulutsa kotentha kapena kupondaponda.

Mavavu a BIMETALLIC

Izi zimapangitsa kuphatikiza kwangwiro kwa zipangizo zotheka zonse tsinde ndi mutu.

MAVAVU OYERA

Ukadaulo uwu umagwiritsidwa ntchito mbali imodzi pakuchepetsa thupi, komanso kuziziritsa. Kudzazidwa ndi sodium (malo osungunuka 97,5ºC), imatha kusamutsa kutentha kuchokera kumutu wa valve kupita ku tsinde kudzera mumadzimadzi oyambitsa sodium, ndikuchepetsa kutentha kwa 80º mpaka 150ºC.