The valavu limagwirira injini, chipangizo ndi mfundo ntchito

Zamkatimu

Makina a valve ndi oyendetsa nthawi yeniyeni, omwe amaonetsetsa kuti mpweya wamafuta osakanikirana ndi mpweya umapezeka pamagetsi a injini ndi kutulutsidwa kwa mpweya wotuluka. Mfundo zazikuluzikulu za dongosololi ndi ma valve, omwe, mwa zina, ayenera kutsimikizira kulimba kwa chipinda choyaka moto. Iwo ali pansi pa katundu wolemetsa, choncho ntchito yawo ili pansi pa zofunikira zapadera.

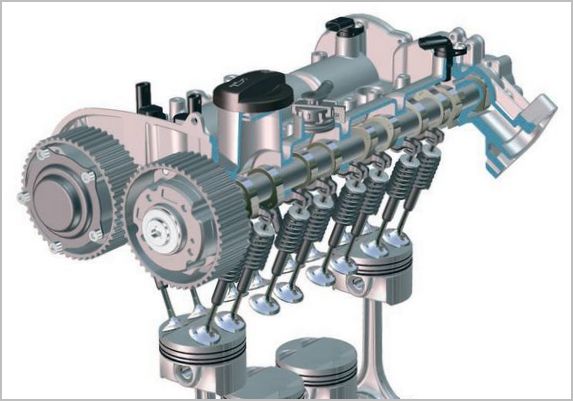

Zinthu zazikulu za makina a valve

Injini imafunikira mavavu osachepera awiri pa silinda, kulowetsa ndi utsi, kuti igwire bwino ntchito. Valavu yokha imakhala ndi tsinde ndi mutu mu mawonekedwe a mbale. Mpando ndi pomwe mutu wa valve umakumana ndi mutu wa silinda. Ma valve olowera ali ndi mainchesi akulu kuposa ma valve otulutsa mpweya. Izi zimatsimikizira kudzazidwa bwino kwa chipinda choyaka moto ndi kusakaniza kwamafuta a mpweya.

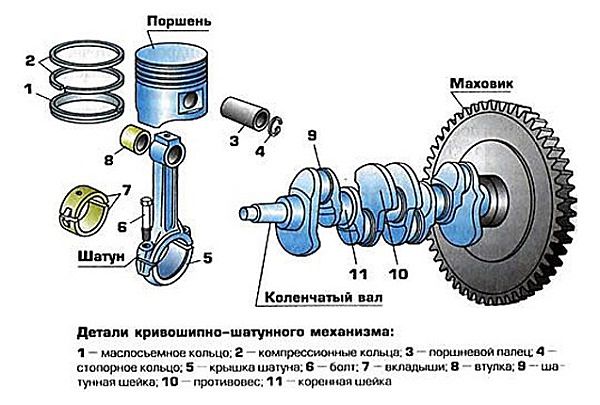

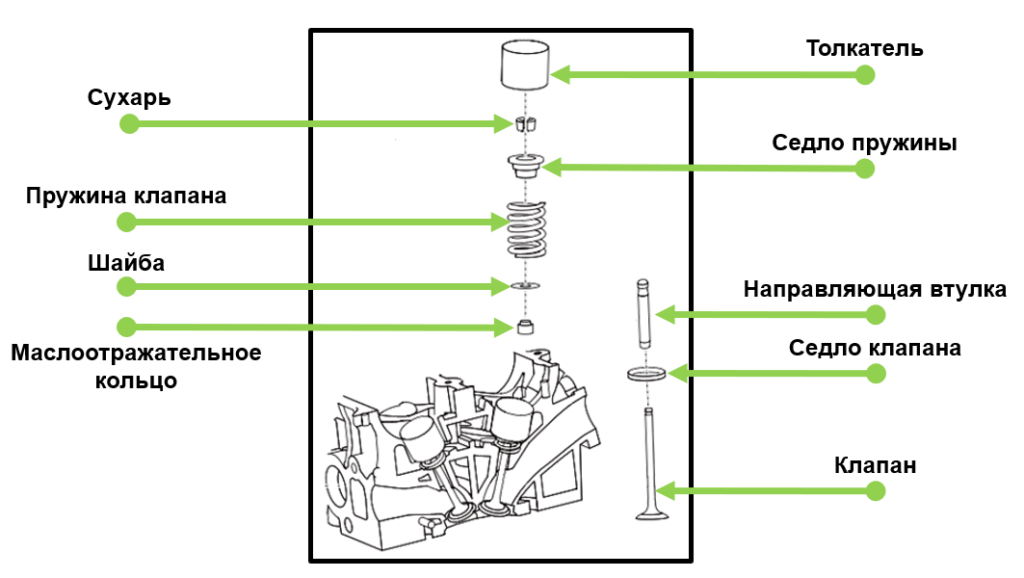

Zinthu zazikulu zamakina:

- mavavu olowera ndi kutulutsa - opangidwa kuti alowe kusakaniza kwamafuta a mpweya ndi mpweya wotulutsa mpweya kuchokera kuchipinda choyaka;

- zitsulo zowongolera - onetsetsani kuti ma valve akuyenda bwino;

- kasupe - kubwezera valavu pamalo ake oyambirira;

- mpando wa valve - malo okhudzana ndi mbale ndi mutu wa silinda;

- crackers - ntchito ngati chithandizo cha kasupe ndi kukonza dongosolo lonse);

- zisindikizo za tsinde la valve kapena mphete zamafuta - zimalepheretsa mafuta kulowa mu silinda;

- pusher - imatumiza kukakamizidwa kuchokera ku camshaft cam.

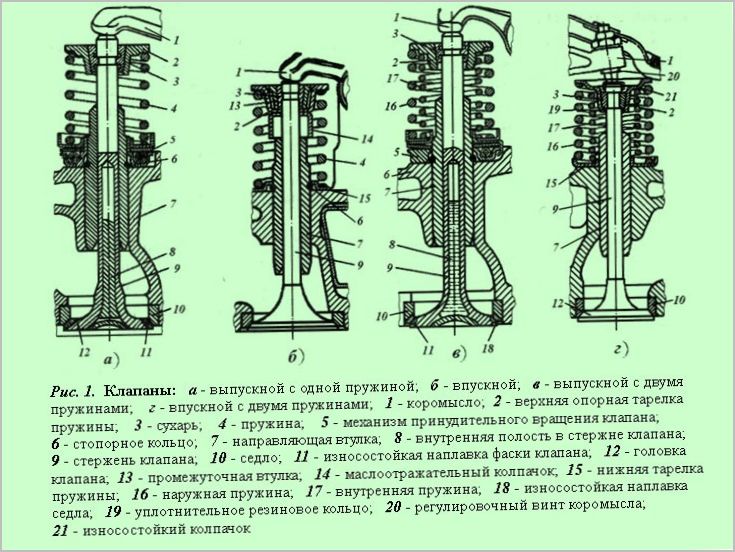

Makamera pa camshaft amasindikiza pa ma valve, omwe amadzaza masika kuti abwerere kumalo awo oyambirira. Kasupe amamangiriridwa ndi ndodo ndi crackers ndi mbale ya masika. Kuti muchepetse kugwedezeka kwamphamvu, osati imodzi, koma akasupe awiri okhala ndi mafunde osunthika amatha kuyika pa ndodo.

Chombo chowongolera ndi chidutswa cha cylindrical. Amachepetsa kukangana ndikuonetsetsa kuti ndodoyo ikuyenda bwino komanso yolondola. Panthawi yogwira ntchito, ziwalozi zimakhalanso ndi nkhawa komanso kutentha. Chifukwa chake, ma alloys osavala komanso osagwira kutentha amagwiritsidwa ntchito popanga. Ma valve otulutsa mpweya ndi ma valve amasiyana pang'ono chifukwa cha kusiyana kwa katundu.

Momwe ma valve amagwirira ntchito

Mavavu nthawi zonse amakumana ndi kutentha kwambiri komanso kupanikizika. Izi zimafuna chidwi chapadera pa mapangidwe ndi zipangizo za zigawozi. Izi ndi zoona makamaka pa gulu lotulutsa mpweya, popeza mpweya wotentha umatulukamo. Ma valve otulutsa mpweya pa injini za mafuta amatha kutentha mpaka 800˚C - 900˚C, ndi injini za dizilo 500˚C - 700C. Katundu pa mbale ya valve yolowera ndi yocheperako kangapo, koma imafika 300˚С, yomwe ilinso yambiri.

Chifukwa chake, ma aloyi achitsulo osagwira kutentha omwe ali ndi zowonjezera zowonjezera amagwiritsidwa ntchito popanga. Kuphatikiza apo, ma valve otulutsa mpweya amakhala ndi tsinde lodzaza ndi sodium. Izi ndi zofunika kuti bwino thermoregulation ndi kuziziritsa mbale. Sodium yomwe ili mkati mwa ndodoyo imasungunuka, imayendayenda, ndipo imatenga kutentha kwina kwa mbale ndikukusamutsira ku ndodo. Mwanjira imeneyi, kutenthedwa kwa gawo kungapewedwe.

Panthawi yogwira ntchito, ma depositi a kaboni amatha kupanga pa chishalo. Kuti izi zisachitike, mapangidwe amagwiritsidwa ntchito pozungulira valavu. Mpandowo ndi mphete yachitsulo yamphamvu kwambiri yomwe imakanikizidwa mwachindunji mumutu wa silinda kuti mugwirizane kwambiri.

Kuphatikiza apo, kuti makinawo agwire bwino ntchito, ndikofunikira kuyang'ana kusiyana komwe kumayendetsedwa ndi kutentha. Kutentha kwakukulu kumapangitsa kuti zigawo ziwonjezeke, zomwe zingapangitse kuti valavu isagwire ntchito. Kusiyana pakati pa makamera a camshaft ndi opukutira kumasinthidwa posankha mawotchi apadera achitsulo a makulidwe enaake kapena ma pushers okha (magalasi). Ngati injini imagwiritsa ntchito zonyamula ma hydraulic, ndiye kuti kusiyana kwake kumasinthidwa.

Chilolezo chachikulu kwambiri chimalepheretsa valavu kuti isatseguke bwino ndipo ma cylinders amadzaza ndi kusakaniza kwatsopano bwino. Kuchepa kwapang'ono (kapena kusowa kwake) sikungalole kuti ma valve atseke kwathunthu, zomwe zingayambitse kutentha kwa valve ndi kuchepa kwa injini.

Kugawa ndi kuchuluka kwa mavavu

Mtundu wapamwamba wa injini ya sitiroko inayi umafuna ma valve awiri okha pa silinda kuti agwire ntchito. Koma injini zamakono zimayang'anizana ndi zofuna zambiri zokhudzana ndi mphamvu, kugwiritsa ntchito mafuta ndi kulemekeza chilengedwe, kotero izi sizili zokwanira kwa iwo. Popeza ma valve ochulukirapo, zimakhala zogwira mtima kwambiri kudzaza silinda ndi mtengo watsopano. Nthawi zosiyanasiyana, njira zotsatirazi zidayesedwa pa injini:

- valve zitatu (zolowera - 2, zotulutsira - 1);

- vavu anayi (kulowetsa - 2, kutulutsa - 2);

- valve zisanu (zolowera - 3, kutulutsa - 2).

Kudzaza bwino ndi kuyeretsa masilindala kumatheka ndi ma valve ambiri pa silinda. Koma izi zimasokoneza kapangidwe ka injini.

Masiku ano, injini zodziwika kwambiri ndi mavavu 4 pa silinda. Woyamba wa injini izi anaonekera mu 1912 pa Peugeot Gran Prix. Panthawi imeneyo, yankho limeneli silinagwiritsidwe ntchito kwambiri, koma kuyambira 1970, magalimoto opangidwa ndi misala omwe ali ndi ma valve ambiri anayamba kupanga.

Mapangidwe a galimoto

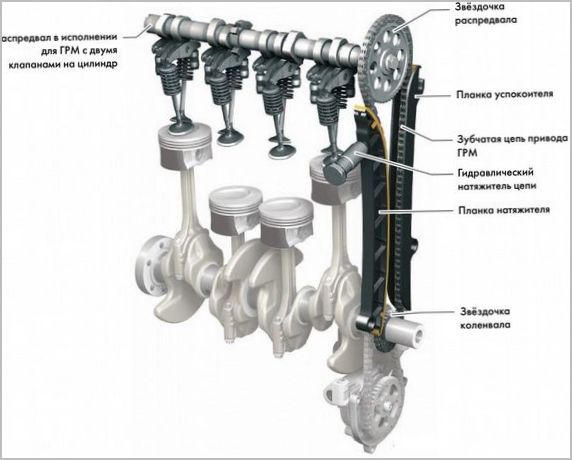

The camshaft ndi nthawi yoyendetsa galimoto ndizomwe zimakhala ndi ntchito yolondola komanso yanthawi yake ya makina a valve. Mapangidwe ndi kuchuluka kwa ma camshaft amtundu uliwonse wa injini amasankhidwa payekha. Gawo ndi tsinde lomwe pali makamera a mawonekedwe enaake. Akatembenuka, amaika mphamvu pa ma pushrods, ma hydraulic lifters kapena rocker arms ndikutsegula ma valve. Mtundu wa dera zimadalira injini yeniyeni.

Camshaft ili molunjika pamutu wa silinda. Kuyendetsa kwa izo kumachokera ku crankshaft. Itha kukhala unyolo, lamba kapena zida. Chodalirika kwambiri ndi unyolo, koma chimafuna zipangizo zothandizira. Mwachitsanzo, unyolo kugwedera damper (damper) ndi tensioner. Liwiro la kuzungulira kwa camshaft ndi theka la liwiro la kuzungulira kwa crankshaft. Izi zimatsimikizira ntchito yawo yogwirizana.

Chiwerengero cha ma camshafts chimadalira kuchuluka kwa ma valve. Pali njira ziwiri zazikulu:

- SOHC - ndi tsinde limodzi;

- DOHC - mitsinje iwiri.

Mavavu awiri okha ndi okwanira pa camshaft imodzi. Imazungulira ndikutsegula mosinthana ma valve olowetsa ndi utsi. Ma injini anayi odziwika kwambiri amakhala ndi ma camshaft awiri. Imodzi imatsimikizira kugwira ntchito kwa ma valve olowera, ndipo ina imatsimikizira ma valve otulutsa mpweya. Ma injini amtundu wa V ali ndi ma camshaft anayi. Awiri mbali iliyonse.

Makamera a camshaft samakankhira tsinde la valve mwachindunji. Pali mitundu ingapo ya "intermediaries":

- zodzigudubuza (rocker mkono);

- makina okankhira (magalasi);

- ma hydraulic pushers.

Ma roller levers ndiye njira yabwino kwambiri. Zomwe zimatchedwa zida za rocker zimagwedezeka pazitsulo za pulagi ndikuyika mphamvu pa hydraulic pusher. Kuti muchepetse kukangana, chodzigudubuza chimaperekedwa pa lever yomwe imalumikizana mwachindunji ndi kamera.

Muchiwembu china, ma hydraulic pushers (gap compensators) amagwiritsidwa ntchito, omwe amakhala molunjika pa ndodo. Ma compensators a Hydraulic amangosintha kusiyana kwamafuta ndikupatsa makinawo kuti azigwira bwino ntchito. Gawo laling'onoli lili ndi silinda yokhala ndi pisitoni ndi kasupe, ndime zamafuta ndi valavu yoyendera. Ma hydraulic pusher amayendetsedwa ndi mafuta operekedwa kuchokera ku injini yopangira mafuta.

Makasitomala amakina (magalasi) ndi tchire lotsekedwa mbali imodzi. Amayikidwa mu nyumba yamutu wa silinda ndipo amasamutsa mwachindunji mphamvu ku tsinde la valve. Zoyipa zake zazikulu ndizofunika kusintha nthawi ndi nthawi mipata ndikugogoda mukamagwira ntchito ndi injini yozizira.

Phokoso kuntchito

Vuto lalikulu la valve ndikugogoda pa injini yozizira kapena yotentha. Kugogoda pa injini yozizira kumatha kutentha kukakwera. Zikatenthedwa ndikukula, kusiyana kwa kutentha kumatseka. Kuonjezera apo, kukhuthala kwa mafuta, omwe samayenda mu voliyumu yoyenera kulowa muzitsulo za hydraulic, kungakhale chifukwa. Kuipitsidwa kwa ngalande zamafuta a compensator kungakhalenso chifukwa cha kugunda kwapang'onopang'ono.

Mavavu amatha kugogoda pa injini yotentha chifukwa cha kutsika kwamafuta pamakina opaka mafuta, zosefera zamafuta zonyansa, kapena chilolezo cholakwika chamafuta. M'pofunikanso kuganizira kavalidwe kachilengedwe ka ziwalo. Zowonongeka zitha kukhala mu makina a valve okha (kuvala masika, manja owongolera, ma tappets a hydraulic, etc.).

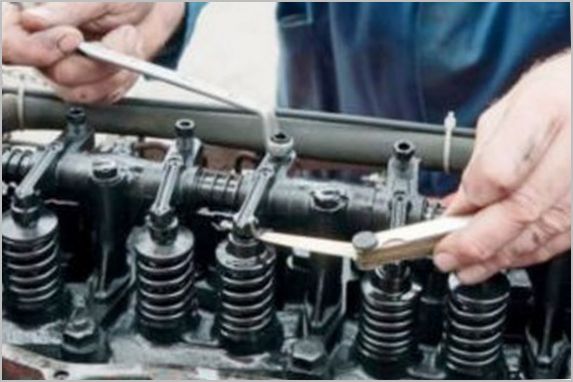

Kusintha kwa chilolezo

Zosintha zimangopangidwa pa injini yozizira. Kusiyana kwamakono kwamafuta kumatsimikiziridwa ndi ma probes apadera achitsulo amitundu yosiyanasiyana. Kusintha kusiyana pa manja a rocker pali chomangira chapadera chosinthira chomwe chimatembenuka. Mu machitidwe okhala ndi pusher kapena shims, kusintha kumapangidwa posankha magawo a makulidwe ofunikira.

Ganizirani njira yosinthira mavavu a injini ndi ma pushers (magalasi) kapena ma washers:

- Chotsani chivundikiro cha valve ya injini.

- Tembenuzirani crankshaft kuti pisitoni ya silinda yoyamba ikhale pamwamba pakufa. Ngati kuli kovuta kuchita izi ndi zizindikiro, mutha kumasula pulagi ya spark ndikuyika screwdriver m'chitsime. Kukwera kwake kokwera kudzakhala pakati.

- Pogwiritsa ntchito makina ojambulira, yesani kutuluka kwa valve pansi pa makamera omwe sakukanikiza pa tappets. Pulogalamuyo iyenera kukhala yolimba, koma osati kusewera kwaulere. Lembani nambala ya valve ndi mtengo wa chilolezo.

- Tembenuzani crankshaft one revolution (360 °) kuti mubweretse piston ya 4th cylinder ku TDC. Yezerani chilolezo pansi pa mavavu ena onse. Lembani deta.

- Onani kuti ndi mavavu ati omwe salolera. Ngati alipo, sankhani zopukutira za makulidwe omwe mukufuna, chotsani ma camshaft ndikuyika magalasi atsopano. Izi zimamaliza ndondomekoyi.

Ndi bwino kuyang'ana mipata iliyonse 50-80 makilomita zikwi. Miyezo yovomerezeka yovomerezeka imatha kupezeka m'mabuku okonza magalimoto.

Chonde dziwani kuti ma valve olowera ndi otulutsa nthawi zina amatha kukhala osiyana.

Njira yogawa gasi yosinthidwa bwino imawonetsetsa kuti injini yoyatsira mkati imagwira ntchito bwino. Izi zidzakhalanso ndi zotsatira zabwino pa injini chuma ndi dalaivala chitonthozo.