Momwe mungakonzere mpope wowongolera mphamvu nokha

Zamkatimu

- madzimadzi mlingo diagnostics ndi mpweya loko kupopa

- Zizindikiro za kulephera kwa chiwongolero cha mphamvu ndi zomwe zingayambitse

- Kuchepetsa mlingo wa madzimadzi ogwira ntchito:

- Kumveka kowonjezera, kuyimba muluzu uku mukutembenuza chiwongolero ndi injini ikuyenda:

- Popanda ntchito kapena pa liwiro lotsika, mphamvu yayikulu imafunika kutembenuza chiwongolero:

- Lamba woyendetsa akachotsedwa, kuseweredwa kwakutali kapena kozungulira kwa pampu shaft kumamveka:

- Kugwedezeka kapena kugwedezeka mukamatembenuza chiwongolero mukuyendetsa:

- Pampu yowongolera mphamvu imafunikira chidwi chapadera

- Kukonzekera kukonza pampu

- Pampu disassembly, kuthetsa mavuto

- Kutayikira chifukwa cha ma hoses owonongeka, zisindikizo kapena ma gaskets.

- lamba woyendetsa ndi womasuka kapena watha;

- mayendedwe ovala kapena shaft shaft;

- ma valve otsekedwa;

- madzi oundana.

- pampu yoyendetsa mphamvu yolakwika;

- kutsekeka kwa hydraulic system;

- otsika madzimadzi mlingo.

- pampu yonyamula iyenera kusinthidwa.

- lamba woyendetsa ndi womasuka kapena watha;

- pampu yoyendetsa mphamvu yolakwika;

- valavu yowongolera yolakwika;

- otsika madzimadzi mlingo;

- mpweya mu dongosolo.

- Nthawi zambiri, kubereka kumalephera, choncho onetsetsani kuti mwasungira chatsopano. Nthawi zambiri amakhala ndi mainchesi akunja a 35 mm ndipo amalembedwa 6202, ngakhale zosankha zina ndizotheka.

- Mphete ziwiri za rabara, chisindikizo chamafuta, gasket ndi mawotchi awiri amkuwa. Zonsezi zitha kusinthidwa ndi zida zokonzetsera pampu yowongolera mphamvu, yomwe imapezeka m'sitolo yamagalimoto.

- Mzimu woyera wowonda kapena WD-40.

- Kuyeretsa nsalu.

- Sandpaper kuchokera P1000 mpaka P2000. Zitha kutenga zambiri ngati pakufunika kugaya.

- Sirinji yayikulu ndi chidebe chopopera mafuta mu thanki.

- ma wrenches ndi mitu ya 12, 14, 16 ndi 24;

- chokoka chozungulira;

- nyundo;

- zokopa;

- kuchulukitsidwa;

- kubowola magetsi ndi kubowola pang'ono 12 mm kapena kukulirapo.

Power chiwongolero (GUR) ndi mbali ya makina chiwongolero ndipo likupezeka pafupifupi galimoto iliyonse yamakono. Chiwongolero champhamvu chimakulolani kuti muchepetse kwambiri mphamvu zolimbitsa thupi zomwe zimafunikira kuti mutembenuzire chiwongolero, komanso kumathandizira kuyendetsa bwino komanso kukhazikika kwagalimoto pamsewu. Ngati hydraulic system ikalephera, chiwongolero chimasungidwa koma chimakhala cholimba.

Dongosolo lonse ndi lodalirika ndipo silimayambitsa mavuto kwa eni magalimoto. Ndikofunikira kuyang'anira kuchuluka kwa mafuta mu tanki yosungiramo zinthu ndipo, ngati kuchepa kodziwika, fufuzani kulimba kwa dongosololi, kupeza ndi kuthetsa kutayikira, makamaka pamalo omwe mapaipi amagwirizanitsidwa ndi zopangira.

Kusintha kwanthawi zonse kwamadzi onyansa komanso otopa kudzakulitsa moyo wa hydraulic booster. Izi zichitike kamodzi pa zaka ziwiri zilizonse.

Muyeneranso kulabadira mkhalidwe wa lamba woyendetsa pampu. Zimachitika kuti zimafunika kusintha kapena kuzimitsa, ndipo ngati zitavala, zisinthe. Kuti mumangitse kapena kuchotsa lamba, nthawi zambiri mumayenera kumasula bolt ndikusuntha nyumba ya mpope momwe mukufunira.

madzimadzi mlingo diagnostics ndi mpweya loko kupopa

Madzi amadzimadzi amasintha ndi kutentha. Kuti mutenthe mpaka 80 ° C, pa liwiro lopanda pake la injini yoyaka mkati, tembenuzirani chiwongolero chanthawi zingapo kuchokera pamalo amodzi kupita ku ena. Izi zithandizanso kuchotsa matumba a mpweya ku hydraulic system.

Osagwira chiwongolero pamalo owopsa kwa masekondi opitilira asanu, kuti madziwo asaphike ndikuwononga mpope kapena zida zina zowongolera mphamvu. ndiye kuyimitsa injini kuyaka mkati ndi kuzindikira mlingo wa madzimadzi ntchito.

Ngati pali mpweya wotsala mu dongosolo, izo compress pamene injini ikuyenda. Izi zipangitsa kuti mulingo wamadzimadzi utsike. Choncho, fufuzaninso mlingo mu thanki ndi injini ikuyenda kuti muwonetsetse kuti palibe kusiyana.

Onjezerani madzi ngati kuli kofunikira.

Njira yosavutayi nthawi zambiri imathetsa mavuto ndi chiwongolero chamagetsi. Apo ayi, matenda owonjezera adzafunika.

Zizindikiro za kulephera kwa chiwongolero cha mphamvu ndi zomwe zingayambitse

Kuchepetsa mlingo wa madzimadzi ogwira ntchito:

Kumveka kowonjezera, kuyimba muluzu uku mukutembenuza chiwongolero ndi injini ikuyenda:

Popanda ntchito kapena pa liwiro lotsika, mphamvu yayikulu imafunika kutembenuza chiwongolero:

Lamba woyendetsa akachotsedwa, kuseweredwa kwakutali kapena kozungulira kwa pampu shaft kumamveka:

Kugwedezeka kapena kugwedezeka mukamatembenuza chiwongolero mukuyendetsa:

Kugwedezeka kapena kugwedezeka kungayambitsidwenso ndi zifukwa zosakhudzana ndi chiwongolero cha mphamvu - kusanja kolakwika kwa magudumu, kuyimitsidwa kapena kulephera kwa chiwongolero. Zolondola diagnostics a mphamvu chiwongolero ndi zotheka kokha pa choyimira chapadera hayidiroliki.

Pampu yowongolera mphamvu imafunikira chidwi chapadera

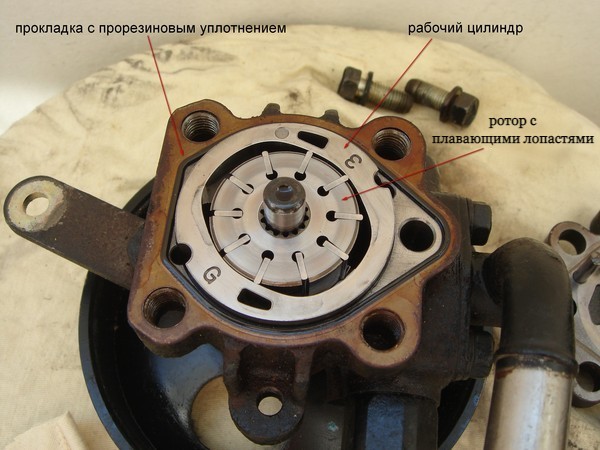

Chinthu chovuta kwambiri komanso chosatetezeka cha chiwongolero cha mphamvu ndi mpope, womwe umayendetsedwa ndi injini ya galimoto ndikupopera madzi ogwirira ntchito mozungulira. Nthawi zambiri ndi pampu yamtundu wa vane, yomwe imasiyanitsidwa ndi mtundu komanso magwiridwe antchito apamwamba.

Kuthamanga kwa hydraulic komwe kumapanga kumatha kufika 150 bar. Pampu yozungulira imazunguliridwa ndi lamba woyendetsa kuchokera ku crankshaft. Panthawi yogwira ntchito, pampuyo imayendetsedwa ndi katundu wambiri. Ndi iye amene nthawi zambiri amakhala gwero la mavuto pa ntchito chiwongolero ndi amafuna kukonza kapena m'malo.

Kulephera kwa pampu kumatha chifukwa cha kutenthedwa, kuipitsidwa kwa hydraulic system, kusakwanira kwamadzimadzi ogwirira ntchito kapena kusagwirizana ndi zofunikira.

Ngati mupitiliza kuyendetsa ndi pampu yolakwika ya hydraulic chiwongolero, izi zimatha kuyambitsa kulephera kwa zigawo zina za chiwongolero chamagetsi. Choncho, sikoyenera kuchedwetsa kukonza kapena kusinthidwa.

Mutha kulumikizana ndi oyendetsa galimoto, kapena mutha kusunga ndalama zabwino ndikuyesa kukonza pampu nokha. Sichifuna zipangizo zamakono kapena ziyeneretso zapadera. Ndikokwanira kukhala ndi chikhumbo, nthawi ndi zochitika zina pochita ntchito zamakina, komanso chidwi ndi kulondola.

Kukonzekera kukonza pampu

Kuti mudzipangitse nokha ndikukonza pampu yowongolera mphamvu, mudzafunika zida zina, zida zosinthira ndi zida.

Zida zofunika:

Kuti mupewe zolakwika pakukonzanso, konzani malo ogwirira ntchito okhala ndi mapepala owerengeka. ndikofunikira kukhala ndi benchi yogwirira ntchito yokhala ndi vise.

Pampu disassembly, kuthetsa mavuto

Pakhoza kukhala kusiyana pakati pa mapangidwe a mpope wa makina amitundu yosiyanasiyana, koma masitepe oyambira ndi kukonzanso ndi ofanana. Choyamba muyenera kupopera mafuta mu dongosolo ndi syringe. Kenako tulutsani machubuwo ndikumanga mabowo otuluka ndi chiguduli kuti dothi lisalowe mkati.

Kuti muchotse mpope, muyenera kumasula bolt yomwe imayiteteza ku bulaketi, ndi bolt ya dongosolo losinthira lamba wagalimoto. Musanagwetse, mpope wochotsedwa uyenera kutsukidwa ndi zosungunulira. Chotsani chophimba chakumbuyo.

Kuti muchite izi, kutengera kapangidwe kake, muyenera kumasula mabawuti 4 kapena kuchotsa mphete yosungirako poigogoda ndi pini (mutha kugwiritsa ntchito msomali) kudzera pabowo lomwe lili pambali. kupitilira apo, kugunda thupi ndi nyundo, timakwaniritsa kuti kasupe mkati mwake amafinya chivundikirocho. Kuti muchotse, mutha kupopera mozungulira mozungulira ndi lubricant ya WD-40.

Timachotsa mosamala zamkati, kukumbukira malo a zigawozo ndikuziyika mwadongosolo. Timachotsa rotor ndi mbale. Chotsani mphete ya rabara yosindikiza poyidula ndi screwdriver. Chotsani silinda yogwira ntchito (stator).

Pamwamba pake pali zizindikiro (chilembo ndi nambala) kuti muyike bwino.

Pansipa pali mbale ina, kasupe ndi chisindikizo chamafuta.

Pambuyo pa disassembly, timatsuka ziwalo zonse ndi mzimu woyera ndikuwunika mosamala.

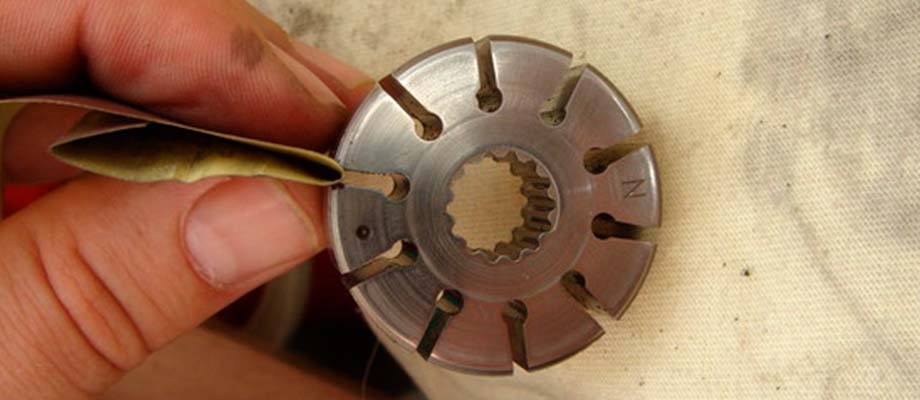

Timatchera khutu ku mkhalidwe wa grooves wa ng'oma ya rotor, m'mphepete mwake ayenera kukhala, akuthwa komanso opanda ma burrs ndi zolakwika zina zomwe zingasokoneze kuyenda kwaufulu kwa masamba.

Kupanda kutero, zolakwika ziyenera kuthetsedwa ndi fayilo ya singano ndi sandpaper. Muyeneranso kugwira ntchito mosamala ndi mbale zokha (masamba). Pewani kuchita changu mopambanitsa ndipo musachite mopambanitsa.

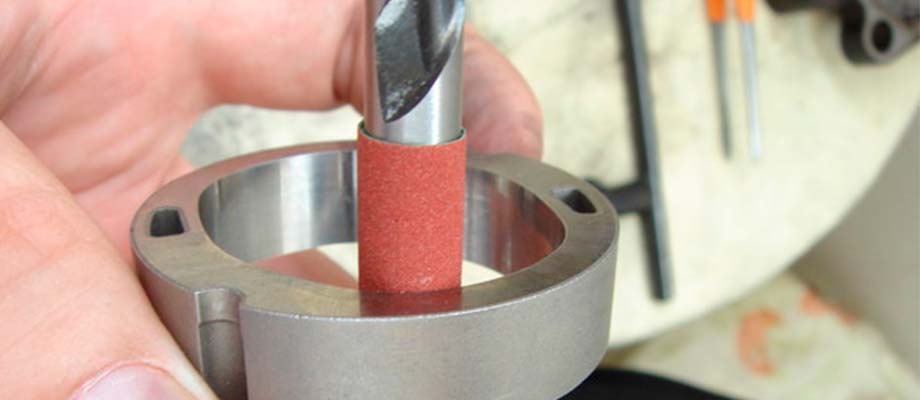

Mkati mwa elliptical pamwamba pa silinda yogwira ntchito iyenera kukhala yosalala. Nthawi zambiri zimakhala zolakwika za ellipse zomwe zimayambitsa kusagwira bwino ntchito kwa mpope. Ngati pali grooves kapena gouges kuchokera ku nkhonya za masamba, iwo ayenera kukhala mchenga.

Njira yoperekera pamanja ndi yayitali komanso yolemetsa. Zitha kukhala zosavuta ngati mugwiritsa ntchito kubowola magetsi. Timakulunga sandpaper pakubowola ndi mainchesi 12 mm kapena kupitilira apo ndikumangirira mu chuck yobowola. Timagaya, kusintha khungu pamene likutha ndikusuntha pang'onopang'ono kuchoka ku coarse kupita ku finer.

Kuti mufike pa bere, muyenera kugwetsa tsinde poligunda ndi nyundo.

Ngati chonyamulacho chiyenera kusinthidwa, chotsani mphete yotsekera ndi chokoka. ndiye muyenera kukanikiza kunyamula kuchokera shaft ndikuyika ina.

Panjira, ndikofunikira kusinthira chisindikizo chamafuta, komanso mphete zonse za o-o ndi ochapira.

Timasonkhanitsa zonse motsatira dongosolo. Mukayika mbale muzitsulo za ng'oma, onetsetsani kuti mbali yawo yozungulira ikuyang'ana kunja.

Pambuyo pokonza mpope, tikulimbikitsidwa kuti musinthe madzi onse ogwira ntchito.

Zingatenge nthawi kuti akupera masamba ndi stator. Pankhaniyi, mpope akhoza kung'ung'udza pang'ono.