Mphamvu ya Hydraulic MAZ

Kusintha kwa chilolezo cha mgwirizano wa mpira wa hydraulic booster MAZ.

Maonekedwe a mipata pazikhomo za mpira amakhudza kwambiri masewero onse a headset. Nthawi zambiri, kusiyana kwa pini ya mpira 9 kumawonjezeka (onani mkuyu 94), kumene ndodo yotalikirapo imagwirizanitsidwa, popeza mphamvu zambiri zimafalitsidwa kudzera mu pini ya mpira kusiyana ndi pini ya mpira wa chiwongolero chowongolera.

Kuti musinthe mipata ya zikhomo za mpira, chowonjezera cha hydraulic chimaphwanyidwa pang'ono. Choncho, ndi bwino kuchita kusintha pa hydraulic booster kuchotsedwa galimoto.

Njira yokhazikitsira ili motere.

Kokani kusintha kwa gap:

- chotsani mapaipi;

- ikani chowonjezera cha hydraulic mu vise ndikumasula nati wa loko pa silinda;

- masulani thupi la hinge kuchokera pa silinda;

- konzani matupi a hinge mu vice, kumasula zotsekera zotsekera pa nati 7 (onani mkuyu 94);

- limbitsani nati 7 mpaka itayima, ndiye limbitsani loko wononga mwamphamvu;

- Sonkhanitsani thupi la mipira ndi silinda. Limbikitsani momwe zidzapitirire ndikumasula kumalo omwe amalola kuti mapaipi agwirizane.

Kusintha kophatikizana kwa pivot:

- konzani hydraulic booster mu vice;

- chotsani chivundikiro 12 kuchokera kwa wogawa, masulani ndi kuchotsa mtedza;

- masulani zomangira zokhala ndi koyilo ndikuchotsa nyumbayo pamodzi ndi koyilo;

- masulani zotsekera zotsekera 29;

- kulunga kapu 29 njira yonse ndikuitembenuza mpaka bowo la zotsekera ligwirizane ndi kapolo wapafupi wa chikho 36;

- limbitsani zotsekera zotsekera mpaka zitasiya;

- kukhazikitsa ndi kuteteza thupi koyilo;

- ikani spool mu manja a thupi, kuvala kapu 32, sungani nati kuti muyime, tsegulani ndi 1/12 kutembenuka ndikudula ulusi;

- kukhazikitsa ndi kuteteza chivundikiro 12 ndi mapaipi;

- kukhazikitsa hydraulic booster pagalimoto.

zotheka kulamulira malfunctions ndi njira kuthetsa iwo amaperekedwa pa khumi tabu.

| Choyambitsa | gwero |

| Kukulitsa kosakwanira kapena kosagwirizana | |

| Kuchulukana kosakwanira kwa lamba woyendetsa pampu | Sinthani kulimba kwa lamba |

| Mulingo wamafuta otsika mu posungira mphamvu poyendetsa | Onjezani mafuta |

| Chithovu chamafuta mu thanki, kukhalapo kwa mpweya mu hydraulic system | Chotsani mpweya ku dongosolo. Ngati palibe mpweya wokhetsa, yang'anani maulalo onse ngati akutuluka. |

| Kuperewera kwathunthu kwa phindu pama liwiro osiyanasiyana a injini | |

| Kutsekeka kwa payipi yotulutsa ndi kukhetsa kwa hydraulic system | Dulani mizereyo ndikuyang'ana patency ya mapaipi ndi ma hoses omwe akuphatikizidwamo |

| Palibe kuthamanga potembenukira ku mbali imodzi | |

| Kugwidwa kwa chiwongolero cha spool chowongolera magetsi | Phatikizani wogawayo, pezani ndikuchotsa zomwe zimayambitsa kujowina |

| Kugwedeza kwa kapu yozungulira ya chala cha hydraulic servomotor | Phatikizani chowonjezera cha hydraulic ndikuchotsa chomwe chimapangitsa kuti chikhomo chija |

| Kubwerera kumbuyo polumikizana ndi spool ndi galasi la pini ya mpira wa chiwongolero chowongolera | Chotsani chivundikiro chakutsogolo cha wogawa, chotsani masewerowo mwa kulimbitsa nati mpaka kusiyana pakati pa mtedza ndi spool kusankhidwa, ndiye pini ya cotter. |

MAZ hydraulic booster kukonza

Kuchotsa hydraulic booster m'galimoto. Kuti muchotse muyenera:

- kulumikiza kupanikizika ndi kukhetsa ma hoses kuchokera ku hydraulic booster;

- masulani nati wa bawuti yolumikizira mutagwira pini pamutu wa ndodo ya hydraulic servomotor, ndikugwetsa bawutiyo kuchokera m'bulaketi;

- kugunda pamutu wa ndodo ya hydraulic booster;

- masulani ndi kumasula mtedza woteteza hydraulic booster ku chowongoleredwa ndi mkono wotsatira;

- pogwiritsa ntchito nkhonya, kanikizani zala zanu kuchokera kumabowo a mkono wowongolera ndi ulalo wotsatira. Chotsani chowonjezera cha hydraulic. Njira yochotsera ma hydraulic booster ndi motere: chotsani mapaipi ndi zida;

- kumasula ulusi wolumikiza mutu wa tsinde ndi tsinde ndikumasula mutu. Chotsani chochapira chakunja; chivindikiro;

- pamene chitsamba cha rabara chatha, sungunulani mutu, womwe umamasula mtedza ndikusindikiza zitsulo zachitsulo, ndiyeno phula la rabara;

- chotsani chotchinga chogwira chivundikiro, chivundikiro ndi makina ochapira amkati kuchokera paphiri;

- masulani zomangira zomwe zikugwira chivundikiro cha silinda yowongolera, chotsani chochapira, chotsani mphete yosungira potsitsa chivundikiro cha silinda kumbuyo, chotsani chivundikirocho;

- chotsani pisitoni ndi ndodo ndikuyiphwanya;

- masulani nati wa loko wa silinda ndikutulutsa silinda;

- chotsani zingwe zomangirira zopangitsa za mpira ndi zotupa zokha;

- masulani zotsekera zotsekera, masulani nati yosinthira 7 (onani mkuyu 94), chotsani chopukusira 8, kasupe, crackers ndi pini ya mpira 9;

- masulani zomangira zomangira chivundikiro 12 ndikuchotsa chivundikirocho; masulani nati yomangira koyilo ndikuimasula, chotsani kapu 32;

- masulani zomangira zomwe zimagwira thupi la koyilo, tulutsani thupi, tulutsani koyilo;

- masulani zotsekera zotsekera, masulani pulagi 29, chotsani bawuti, chopondera 8, kasupe, ma crackers ndi pini 10;

- chotsani galasi 36;

- masulani kapu ya cheki valavu 35 ndikuchotsa kasupe wa mpira i.

Pambuyo pa disassembly, yang'anani mosamala mbali za hydraulic booster.

Zolemba ndi ma nick siziloledwa pamtunda wa spool, galasi la pini yowongolera ndi matupi awo. Malo othamangirapo pazitsulo za mpira ndi rocker ayenera kukhala opanda mano ndi kuvala mopitirira muyeso, ndipo mphete za mphira ziyenera kusonyeza kuwonongeka ndi kuwonongeka.

Ngati kuwonongeka kwapezeka, sinthani zigawozi ndi zatsopano.

Ikani chowonjezera cha hydraulic mu dongosolo lakumbuyo lakuchotsa. Pamaso msonkhano, akusisita pamalo a koyilo, galasi ndi zala; mafuta ndi woonda wosanjikiza wa lubricant ndi kuonetsetsa kuti koyilo ndi kapu kuyenda momasuka mu housings awo, popanda kusokonezedwa.

Sinthani chilolezo cholumikizira mpira monga tafotokozera pamwambapa.

Mukatha kusonkhana, thirirani mayendedwe a mpira ndi mafuta kudzera mu oiler 18.

Ikani chowonjezera cha hydraulic pagalimoto munjira yochotsamo.

Mukayika chowonjezera cha hydraulic, sungani mtedza woteteza mapini mwamphamvu ndikumapukuta mosamala.

Kukonzekera kwa hydraulic booster MAZ

Panthawi yogwira ntchito yagalimoto, yang'anani mwadongosolo kukhazikika kwa hydraulic booster ku bulaketi ya chimango chagalimoto, kumangirira kwa pulley ya hydraulic booster pump, nthawi ndi nthawi kumangitsa mtedza wa zida za mpira wogawa.

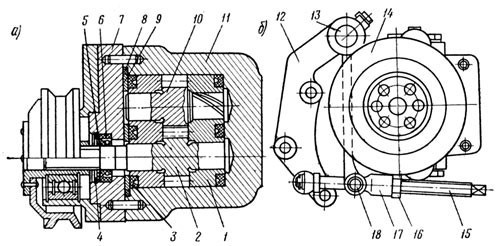

Yang'anani kuthamanga kwa lamba woyendetsa pampu pakukonza kulikonse. Kuthamanga kwa lamba kumasinthidwa ndi screw 15 (mkuyu 96, b). Ndi zovuta zolondola, kupatuka pakati pa lamba pansi pa mphamvu ya 4 kg kuyenera kukhala mkati mwa 10-15 mm. Mukakonza, tsekani wononga ndi nati 16.

Werenganinso 8350 ndi 9370 kukonza kalavani

Nthawi ndi nthawi, pa nthawi yomwe yasonyezedwa pa tchati chopaka mafuta, yang'anani kuchuluka kwa mafuta mu hydraulic booster pump reservoir, sinthani mafuta mu hydraulic booster system, ndikutsuka sefa yosungiramo madzi.

Tsiku ndi tsiku fufuzani kulimba kwa maulumikizidwe ndi zisindikizo za hydraulic booster, pampu, mapaipi ndi ma hoses a dongosolo.

Pachiwongolero cha mphamvu, gwiritsani ntchito mafuta oyera okha, osefedwa monga momwe zafotokozedwera pa tchati chopaka mafuta. Thirani mafuta mu mpope posungira 10-15 mamilimita m'munsimu chapamwamba m'mphepete mwa nkhokwe kudzera mu mphako ndi awiri mauna abwino. Mukathira mafuta, musagwedeze kapena kugwedeza mumtsuko.

Kugwiritsiridwa ntchito kwa mafuta oipitsidwa kumabweretsa kuvala kofulumira kwa silinda yowongolera mphamvu, magawo ogawa ndi mapampu.

Poyang'ana mlingo wa mafuta mu posungira posungira pa kukonza kulikonse (TO-1), mawilo akutsogolo a galimoto ayenera kuikidwa molunjika.

Pa TO-2 iliyonse, chotsani fyuluta mu thanki ndikutsuka. Ngati fyulutayo yatsekedwa kwambiri ndi ma depositi owumitsidwa, yambani ndi chochepetsera utoto wagalimoto. Musanachotse fyulutayo, yeretsani bwinobwino chivindikiro cha thanki ya zinyalala.

Mukamasintha mafuta, omwe amachitidwa 2 pa chaka (ndi kukonza nyengo), kwezani chitsulo chamoto kutsogolo kuti mawilo asakhudze pansi.

Kuti muchotse mafuta mu dongosolo, muyenera:

- tsegulani thanki ndipo, mutachotsa chivundikirocho, tsitsani mafuta;

- kulumikiza nozzles kuchokera kumaliseche ndi kukhetsa mapaipi a distribuerar ndi kukhetsa mafuta mpope kudzera mwa iwo;

- pang'onopang'ono kutembenuza flywheel kumanzere ndi kumanja mpaka itayima, tsitsani mafuta mu silinda yamphamvu.

Mukathira mafuta, yatsani chowongolera mphamvu:

- chotsani fyuluta mu thanki, yambani monga tafotokozera pamwambapa;

- yeretsani bwino thanki kuchokera mkati, kuchotsa zotsalira za mafuta oipitsidwa;

- khazikitsani fyuluta yotsuka mu thanki;

- Thirani mafuta atsopano mu thanki kudzera mumphaniyo wokhala ndi mauna awiri abwino ndikudikirira mpaka atuluke mu nozzles.

Mukadzaza mafuta atsopano, onetsetsani kuti mwachotsa mpweya ku dongosolo. Kwa ichi muyenera:

- onjezani mafuta ku thanki pamlingo womwe mukufuna ndipo musakhudze dongosolo kwa mphindi ziwiri;

- yambitsani injini ndikuilola kuti ipite mofulumira kwa mphindi ziwiri;

- Pang'onopang'ono tembenuzirani chiwongolero 2 nthawi zonse kupita kumanja ndi kumanzere mpaka mpweya utuluke pamalo osungiramo madzi. Ngati ndi kotheka, onjezerani mafuta pamlingo womwe uli pamwambapa; kubwezeretsanso chivundikiro cha thanki ndi zomangira zake;

- tembenuzirani mawilo kumanja ndi kumanzere, kuyang'ana ngati chiwongolero chili chosavuta komanso ngati mafuta akuchucha.

Yang'anani kuloledwa kwa zikhomo za mpira ndi injini yomwe ikuyenda pa TO-1 iliyonse, ndikutembenuza chiwongolero molunjika komanso mozungulira.

Sipayenera kukhala sewero pamgwirizano wa tayi. Mu hinge ya chiwongolero ndi injini kuyimitsidwa, sewero sayenera upambana 4 mm, ndi injini kuthamanga - mpaka 2 mm.

Chipangizo ndi ntchito ya hydraulic booster

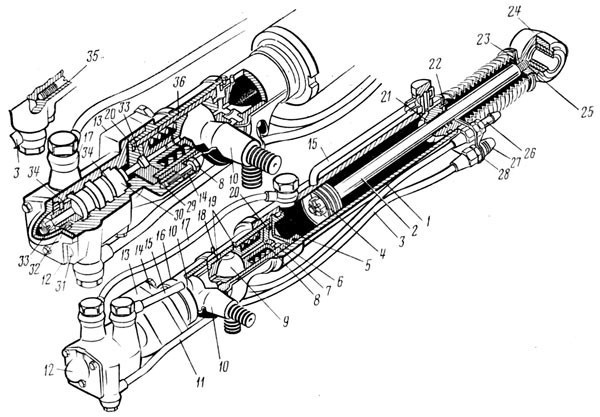

The hydraulic booster (mkuyu 94) ndi gawo lopangidwa ndi wogawira ndi msonkhano wa silinda yamphamvu. Dongosolo la booster hydraulic limaphatikizapo mpope wa NSh-10E woyikidwa pa injini yamagalimoto, thanki yamafuta ndi mapaipi.

Mpunga. 94. GUR MAZ:

1 - silinda yamphamvu; 2 - masamba; 3 - chitoliro chotulutsa; 4 - pisitoni; 5 - nkhuni; 6 - thupi la mayendedwe a mpira; 7 - kusintha kwa backlash kwa mtedza wa longitudinally-stop mpira olowa; 8 - wothamanga; 9 - pini ya mpira wa nthawi yayitali; 10 - kumanga ndodo ya mpira pini; 11 - kukhetsa chitoliro; 12 - chophimba; 13 - nyumba zogawa; 14 - flange; 15 - chitoliro chanthambi mu dzenje pamwamba pa pisitoni yamphamvu yamphamvu; 16 - kolala yomangirira ya chosindikizira; 17 - chitoliro chanthambi m'mphepete mwa pisitoni yamphamvu yamphamvu; 18 - mafuta; 19 - zikhomo kukonza crackers; 20 - kutseka screw; 21 - chivundikiro cha silinda yamphamvu; 22 - phula; 23 - wochapira wamkati womangira chophimba; 24 - kukankhira mutu; 25 - pini ya cotter; 26 - kumangirira kwa mzere wokhetsa; 27 - msonkhano wa mzere wotulutsa; 28 - chofukizira payipi; 29 - sinthani mitu yamagulu olumikizana ndi mpira wa mkono wowongolera; 30 - mchere; 31 - nkhuni; 32 - kapu ya spool; 33 - kuphatikiza bawuti; 34 - njira yolumikizira; 35 - valavu yowunika; 36 - galasi

Wogawa amakhala ndi thupi 13 ndi spool 30. Zitsamba za spool zimasindikizidwa ndi mphete zosindikizira mphira, imodzi mwachindunji m'thupi, ina mu pulagi 32 yolowetsedwa m'thupi ndikutsekedwa ndi kapu 12.

Pali ma grooves atatu a annular mkati mwa thupi la coil. Zowopsa kwambiri zimalumikizidwa ndi kanjira kwa wina ndi mnzake komanso pamzere wothirira wa mpope, zapakati - kudzera mumtsinje wokhetsa kupita ku tanki yapope. Pamwamba pa ng'oma pali mitsinje iwiri ya annular yolumikizidwa ndikulumikiza ngalande 34 ndi ma voliyumu otsekedwa otchedwa reactive chambers.

Thupi la coil limamangiriridwa ku flange ya thupi ndi ma hinge 6. Pali zikhomo ziwiri za mpira m'nyumba 6: 10, pomwe ndodo yowongolera imamangiriridwa, ndi 9, yolumikizidwa ndi ndodo yowongolera nthawi yayitali. Zala zonse ziwiri zimagwiridwa pakati pa mabisiketi ozungulira ndi pulagi 29 ndi mtedza 7 pogwiritsa ntchito akasupe. Kumangirira kwa mabisiketi kumachepa ndi opusitsa 8. Mahinji amatetezedwa ku dothi ndi zisindikizo za mphira zomwe zimayikidwa ku thupi ndi zingwe.

Zala zomwe zili mkati mwa malire ena zimatha kuzungulira mabisiketi, omwe amagwiridwa ndi zikhomo zosweka 19, zomwe zimaphatikizidwa muzitsulo za masikono.

Werengani komanso Makhalidwe aukadaulo a brake system ya trailer GKB-8350, OdAZ-9370, OdAZ-9770

Bipod 36 imayikidwa mu kapu 10, yomwe imatha kusuntha m'nyumba 6 mu njira ya axial mkati mwa 4 mm. Kusunthaku kumachepetsedwa ndi kolala ya cork 29 yokutidwa mu galasi. Mapewa m'malo ovuta kwambiri amakhala kumapeto kwa nyumba 13 ya wogawa komanso kumapeto kwa nyumba 6 ya mayendedwe a mpira. Spool 30 imayendanso ndi chikho 36, chifukwa imalumikizidwa mwamphamvu ndi bolt ndi nati.

Silinda yamphamvu 1 imalumikizidwa kumalekezero ena a hinge body 6 pogwiritsa ntchito ulusi ndipo imatsekedwa ndi nati. Pistoni 4 imayenda mu silinda, yolumikizidwa ndi nati ku ndodo 2. Pistoni imasindikizidwa ndi mphete ziwiri zachitsulo. Mphepete mwa silinda imatsekedwa kumbali imodzi ndi pulagi 5, yosindikizidwa ndi mphete ya mphira, kumbali inayo, ndi chivundikiro 21, chosindikizidwa ndi mphete yomweyo ndi yotsekedwa ndi mphete yosungira ndi washer, yomwe chivundikirocho chimatsekedwa. Tsinde limasindikizidwa pachivundikirocho ndi mphete ya rabara yotetezedwa ndi scraper. Kunja, tsinde limatetezedwa kuti lisaipitsidwe ndi nsapato ya labala yamalata. Pamapeto pa ndodoyo, mutu 24 umakhazikitsidwa ndi kugwirizana kwa ulusi, momwe mphira ndi zitsulo zachitsulo zimayikidwa.

Chitsamba cha rabara chimakhazikitsidwa kumapeto ndi kolala yachitsulo ya tchire ndi mtedza. Mphuno ya silinda yamphamvu imagawidwa ndi pisitoni m'magawo awiri: under-piston ndi over-piston. Mitsemphayi imalumikizidwa ndi mipope ya nthambi 15 ndi 17 yokhala ndi ngalande mumagulu ogawa, kutha ndi njira zomwe zimatsegukira mkati mwa thupi pakati pa mitsinje ya annular.

Mitsempha yomwe ili pansi ndi pamwamba pa pisitoni ya silinda yamphamvu imatha kulumikizidwa kudzera pa cheke valavu 35, yomwe imakhala ndi mpira ndi kasupe wopanikizidwa ndi pulagi.

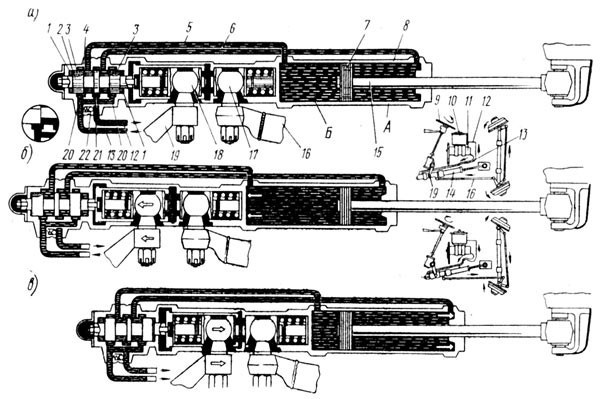

The hydraulic booster imagwira ntchito motere (mkuyu 95). Injini yamagalimoto ikamathamanga, mpope 11 nthawi zonse imapereka mafuta ku hydraulic booster 14, yomwe, kutengera momwe galimoto imayendera, imabwerera ku thanki 10 kapena kudyetsedwa mu imodzi mwazogwira ntchito (A kapena B) ya silinda yamagetsi. 8 kupyola mapaipi 5 ndi 6. Khomo lina likalumikizidwa kudzera pa chingwe cha 12 ndi thanki 10.

Kuthamanga kwa mafuta kudzera muzitsulo 3 mu spool 2 nthawi zonse kumaperekedwa ku zipinda zowonongeka 1 ndipo kumakonda kusuntha spool kumalo osalowerera ndale ponena za thupi.

Pamene galimoto imayenda molunjika (mkuyu. 95, a), mpope amapereka mafuta kudzera kumaliseche payipi 13 kuti kwambiri annular cavities 20 wa distribuerar, ndipo kuchokera pamenepo kudzera mipata pakati pa m'mphepete mwa grooves wa spool. ndi nyumba ku chapakati annular patsekeke 21 ndi kupitirira pa kukhetsa mzere 12 kwa thanki 10 .

Pamene chiwongolero chikutembenuzidwira kumanzere (mkuyu 95, b) ndi kumanja (mkuyu 95, c), chowongolera 19 kupyolera mu pini ya mpira 18 chimachotsa spool kumalo osalowerera ndale ndi kukhetsa 21 mkati. thupi la spool limasiyanitsidwa, ndipo madziwo amayamba kuyenda mumtsempha wofanana wa silinda yamphamvu, kusuntha silinda 8 yokhudzana ndi pisitoni 7, yokhazikika pa ndodo 15. Kuyenda kwa silinda kumaperekedwa ku mawilo owongolera kudzera mu mpira. pini 17 ndi ndodo yakutali XNUMX yogwirizana nayo.

Mukasiya kutembenuza flywheel 9, koyiloyo imayima ndipo thupi limasunthira komweko, ndikusunthira kumalo osalowerera ndale. Mafuta amayamba kugwera mu thanki ndipo mawilo amasiya kupota.

Ma hydraulic booster ali ndi mphamvu zambiri. Kutembenuza mawilo a galimoto, m'pofunika kusuntha spool ndi 0,4-0,6 mm.

Ndi kuwonjezeka kwa kukana kutembenuza mawilo, kuthamanga kwa mafuta muzitsulo zogwirira ntchito za silinda yamphamvu kumawonjezekanso. Kupanikizika uku kumasamutsidwa ku zipinda zomwe zimachitikira ndipo zimakonda kusuntha spool kumalo osalowerera ndale.

Mpunga. 95. Dongosolo la ntchito GUR MAZ:

1 - chipinda chogwira ntchito; 2 - chipolopolo; 3 - njira; 4 - nyumba zogawa; 5 ndi 6 - mapaipi; 7 - pisitoni; 8 - silinda yamphamvu; 9 - chiwongolero; 10 - thanki; 11 - bomba; 12 - kukhetsa payipi; 13 - payipi yamagetsi; 14 - hydraulic booster; 15 - ndodo ya pistoni; 16 - kukankhira kotalika; 17 ndi 18 - zala za mpira; 19 - chiwongolero chowongolera; 20 - patsekeke kuthamanga; 21 - ngalande zamadzimadzi; 22 - valavu

Mpunga. 96. Pampu yowongolera mphamvu MAZ:

bomba; b - chida champhamvu; 1 - dzanja lamanja; 2 - zida zoyendetsedwa; 3 - mphete yosindikiza; 4 - kusunga mphete; 5 - mphete yothandizira; 6 - manja; 7 - chivundikiro; 8 - mphete yosindikiza; 9 - kuyendetsa galimoto; 10 - manja akumanzere; 11 - pampu nyumba; 12 - chithandizo chokhazikika; 13 - olamulira; 14 - dzira; 15 - kukonza wononga; 16 - locknut; 17 - mphanda; 18 - chala

Chifukwa cha kukulitsa mphamvu ya hydraulic booster, mphamvu pa chiwongolero kumayambiriro kwa kutembenuka kwa mawilo sikudutsa 5 kg, ndipo mphamvu yayikulu ndi pafupifupi 20 kg.

Dongosolo la hydraulic booster lili ndi valavu yotetezera yomwe imayikidwa pa silinda yamagetsi. Valavu imayikidwa pa fakitale kuti ikhale ndi mphamvu ya 80-90 kg / cm2. Kusintha kwa vavu ndikoletsedwa muzombo.

Ziyenera kukumbukiridwa kuti kugwira ntchito kwakanthawi kochepa kwa chiwongolero kumaloledwa pamene amplifier sikugwira ntchito, chifukwa izi zimawonjezera khama pa chiwongolero ndikuwonjezera kusewera kwake kwaulere. Liwiro lopanda ntchito la galimoto siliyenera kupitirira 20 km/h.

Pampu yamagetsi yamagetsi ya NSh-10E (mkuyu 96) imayikidwa kumanzere kwa injini ndipo imayendetsedwa kuchokera ku crankshaft ya injini pogwiritsa ntchito V-lamba. Chosungira chamadzimadzi chogwirira ntchito chimayikidwa pa chimango cha radiator.